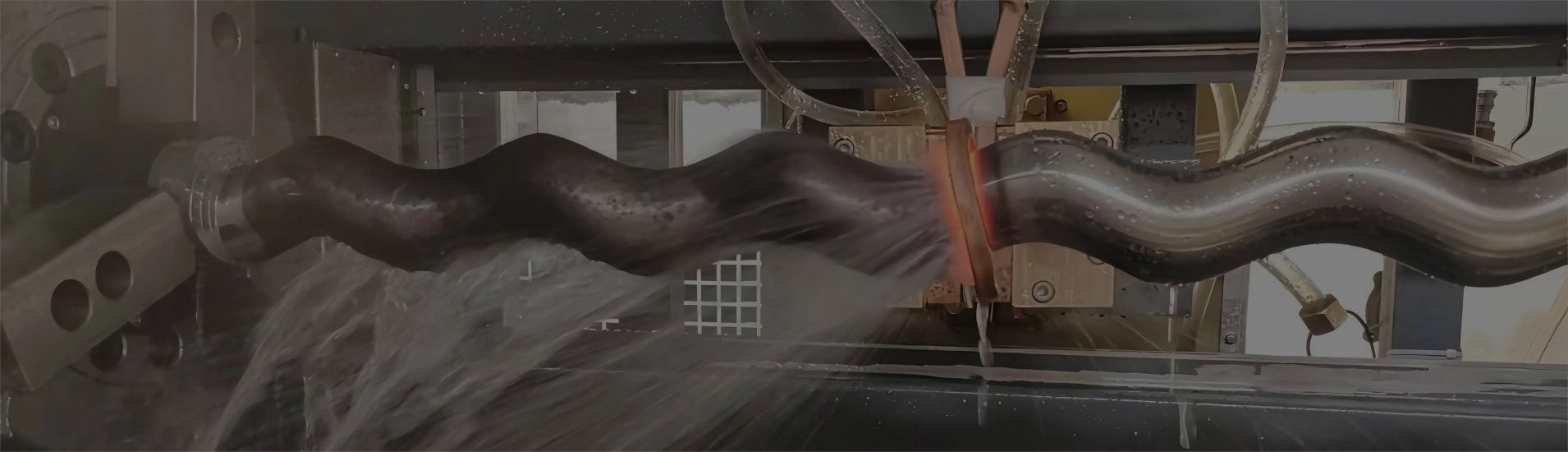

In the evolving landscape of industrial heat treatment, induction hardening machines are essential for enhancing the surface strength of metal components while preserving core toughness. These specialized induction hardening equipment pieces utilize electromagnetic fields to rapidly heat and quench materials, making them indispensable in sectors like automotive, aerospace, and machinery. As demand for durable, high-performance parts grows, leading induction hardening machine manufacturers are innovating with automated systems, energy-efficient designs, and customizable solutions. Whether you're looking for a robust induction hardener for batch production or a precise induction hardener China supplier, this overview spotlights the top players. We begin with Shanghai Junko New Energy Technology Co., Ltd., a standout induction hardening machine manufacturer from China, followed by other industry frontrunners shaping the market in 2025.

As a premier induction hardening machine manufacturer, Shanghai Junko New Energy Technology Co., Ltd. stands out for its commitment to cutting-edge technology and eco-friendly practices. Situated in Shanghai's bustling Changning District, this high-tech enterprise excels in researching, developing, producing, and selling advanced induction hardening machines alongside semiconductor materials. Their core goal is to supply efficient, power-saving induction hardeners that boost manufacturing productivity, foster breakthroughs in material sciences, and support the worldwide push toward renewable energy and sustainability.

Junko Energy's R&D prowess is bolstered by top-tier testing labs and streamlined manufacturing setups, which guarantee that every induction hardening equipment piece meets or exceeds industry benchmarks for quality and functionality. As a customer-oriented induction hardener China provider, they deliver full-spectrum services, including expert advice before purchase, smooth integration during implementation, and reliable ongoing support to optimize user satisfaction and operational uptime.

Their portfolio of induction hardening machines is diverse and adaptable, catering to a range of workpiece sizes and shapes with options for customization. Notable products include:

Vertical Induction Hardening Machine: A vertical CNC-based induction hardener where the Z-axis enables vertical movement of the workpiece, and the A-axis allows 360-degree rotation. This vertical induction hardening machine from Junko Energy supports spot-timed overall hardening, continuous scan hardening, and segmented positioning for shafts. It's ideal for automotive, tractor, textile, and military machinery applications, handling single or batch parts with user-friendly operation and sturdy build.

Disk Induction Hardening Machine: This disk CNC induction hardener features Z-axis vertical motion and A-axis rotation, tailored for gear hardening. It performs fixed-point timed quenching, scan quenching, and segmented operations, making it a versatile induction hardening machine for sale in industries like vehicles and engineering equipment. Competitive induction hardening machine prices ensure accessibility without sacrificing performance.

Horizontal Induction Hardening Machine: Designed with a horizontal clamping system and a mobile platform for tracking, this induction hardener allows multi-directional movement and workpiece rotation for three-axis synchronized quenching. Models like JC-1000W to JC-4000W vary in specs: maximum rotating diameters from 100mm to 500mm, hardening lengths up to 4000mm, and weights up to 1000kg. Features include servo-driven speeds (0-3000mm/min), high accuracy (±0.1mm), and GSK 96 CNC systems for manual or auto modes. This horizontal induction hardening machine excels in aligning sensors for scan quenching on worms or flat parts, with integrated spray systems and intuitive interfaces for easy model switching.

Raceway CNC Hardening Machine for Slewing Rings: A slanted-axis CNC induction hardener at 70 degrees, functioning like a vertical unit with welded frames and dual-roller supports. This CNC induction hardening machine offers continuous and segmental hardening for large bearings and ring channels, used in wind power and construction. Siemens controls enable precise tracking, adjustable gaps, and automatic parameter recording for efficient production.

Whole Teeth Induction Hardening Machine: Focused on hardening gears, bearings, and flat components, this induction hardener supports overall quenching for rings and high-frequency treatments. It's widely applied in wind energy, automotive, and tooling sectors, emphasizing ease of setup and comprehensive capabilities.

Junko Energy's induction hardening machines integrate seamlessly into workflows, offering modularity and competitive pricing as a trusted induction hardener China source.

ENRX ranks among the top induction hardening machine manufacturers, known for their HardLine series that includes horizontal, vertical, and rotary configurations. Their induction hardening equipment emphasizes accuracy, longevity, and adaptability, serving precision needs in automotive and aerospace. With global operations, ENRX delivers customizable induction hardeners that incorporate advanced controls for consistent results, making them a go-to for high-volume hardening tasks.

Part of the Inductotherm Group, Inductoheat is a leading induction hardening machine manufacturer excelling in tailored heat-treating systems. They offer induction hardeners with bespoke coil designs for complex parts like shafts and gears. Their equipment features digital monitoring and efficient power delivery, ideal for industries requiring robust induction hardening machines that reduce cycle times and energy use.

Eldec stands out as an induction hardening machine manufacturer for models like the MIND-S series, which are space-efficient yet powerful for medium-batch production. Their induction hardening equipment includes multi-frequency options for precise surface treatments on tools and components. Focused on affordability and reliability, eldec's induction hardeners are favored in manufacturing for their ease of integration and superior hardening outcomes.

With a strong heritage, Ajax TOCCO is a prominent induction hardening machine manufacturer designing systems for melting and hardening applications. Their induction hardeners cater to heavy industries, featuring durable builds and automation for shaft and gear treatments. Emphasis on innovation ensures their induction hardening machines meet modern demands for speed and environmental compliance.

EMA Indutec provides comprehensive induction hardening equipment, including CNC-controlled units for precise quenching. As an induction hardening machine manufacturer, they specialize in systems for large components, with features like servo drives and programmable interfaces. Their solutions are popular in machine tools and energy sectors for enhancing part durability through efficient hardening processes.

GH Induction is recognized for bespoke induction hardening machines used in quenching, tempering, and brazing. This induction hardening machine manufacturer offers flexible systems for diverse materials, incorporating smart sensors and energy-saving tech. Their global reach makes them a reliable choice for industries seeking tailored induction hardeners that optimize production.

Termomacchine delivers a variety of induction hardening machines suited for different scales, from small to large batches. Their induction hardeners focus on high-temperature precision for metal surfaces, with user-friendly designs. As an induction hardening machine manufacturer, they support sectors like textiles and military with equipment that's easy to maintain and operate.

Linn HIGH TEMP excels in induction hardening equipment for extreme conditions, ideal for mass production in demanding environments. Their machines feature advanced heating controls for uniform hardening, making them a top induction hardening machine manufacturer for industries requiring consistent quality in heat-treated parts.

FOCO Induction offers complete induction hardening systems, including automated lines for steel components like gears. This induction hardening machine manufacturer emphasizes semi-automatic options for efficiency, with competitive induction hardening machine prices. Their equipment is widely used in automotive and construction for reliable surface enhancement.

Other notables include Saet Emmedi for precision induction hardeners in electronics; ALFING for robust shaft systems; Loeser for finishing-integrated equipment; Chengdu Duolin for cost-effective Asian solutions; SMS Elotherm for large-scale operations; Heatking for innovative quenching tech; Denki Kogyo for high-frequency models; KETCHAN Induction for sustainable designs; Thermo Induction from India for forging-focused hardeners; and TY Induction for billet heating variants. These induction hardening machine manufacturers add variety, from niche to broad applications.

In 2025, the induction hardening machine market is expanding, driven by AI-enhanced controls for predictive maintenance and hybrid systems blending induction with other methods for superior precision. Energy efficiency is key, with induction hardener China firms like Junko Energy leading in low-emission designs amid rising green regulations. As electric vehicles and renewables surge, demand for advanced induction hardening equipment will grow, favoring manufacturers who innovate in automation and customization.

In essence, these top induction hardening machine manufacturers, starting with Junko Energy's eco-innovative approach, are vital for durable manufacturing. They supply induction hardening equipment that elevates efficiency and sustainability. When choosing an induction hardening machine manufacturer, weigh factors like scale and support for your needs.

This is the first one.